- IQC

- PQC

- FQC

- OQC

- QA

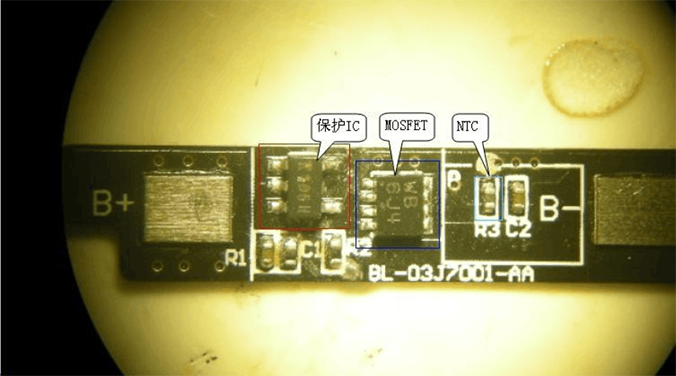

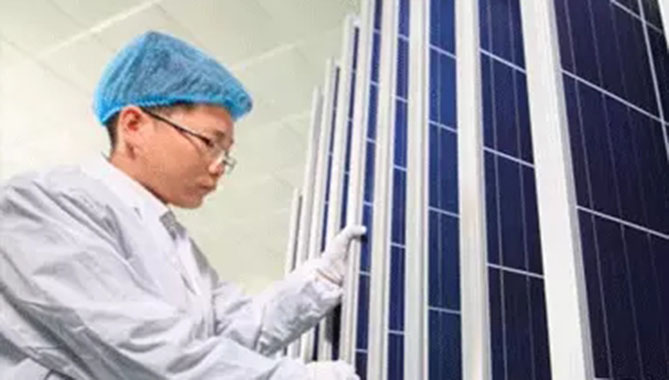

Incoming material inspection includes PCB, components, cables, connectors and other materials inspection. The inspection is carried out according to the US banned standard MIL-STD-105-E II for sampling test. The inspection content is to make check-confirmation of comprehensive identification, appearance, size, performance safety, IEC / GB testing, trial production or reliability testing based on our incoming inspection process and inspection regulations, BOM, drawings, samples, specifications, customers’ specific requirements, etc., to prevent defective products from entering the warehouse and ensure that the material on the line is qualified.

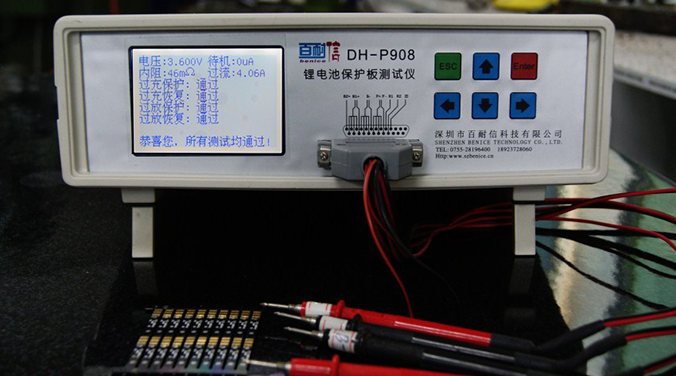

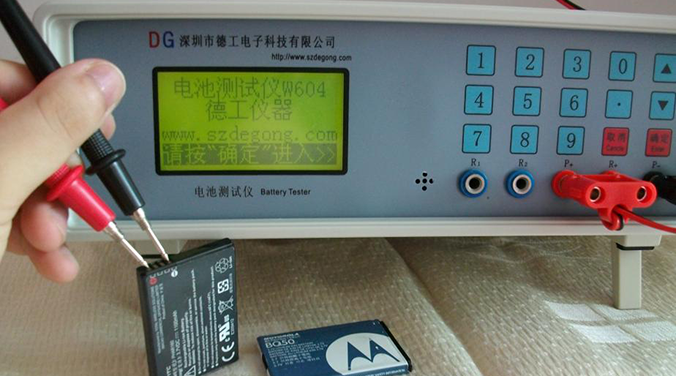

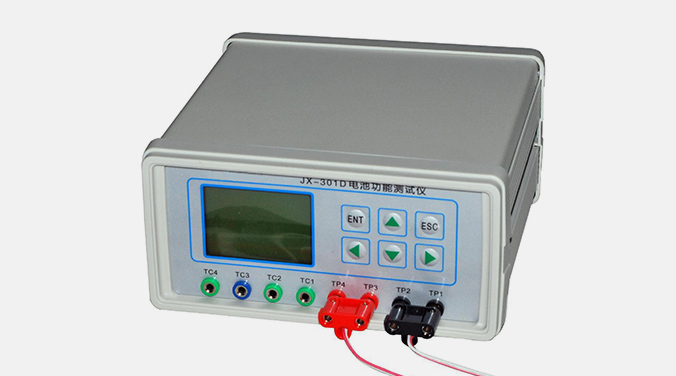

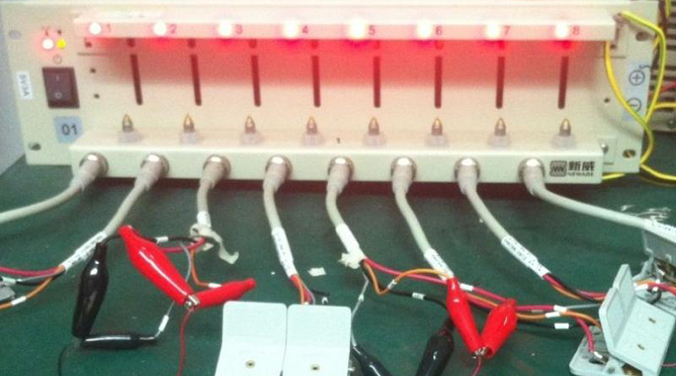

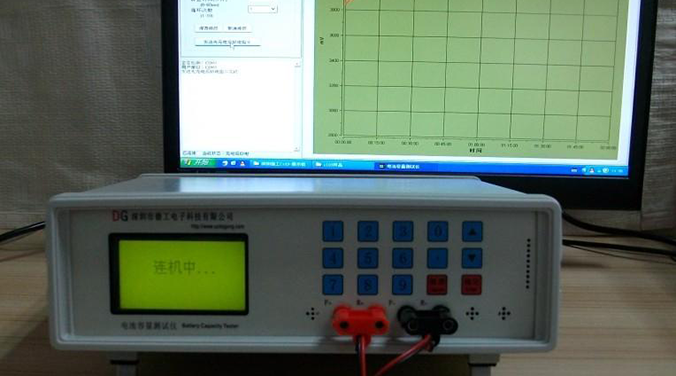

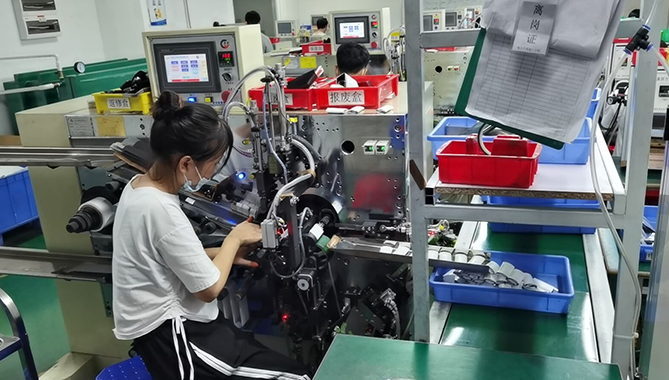

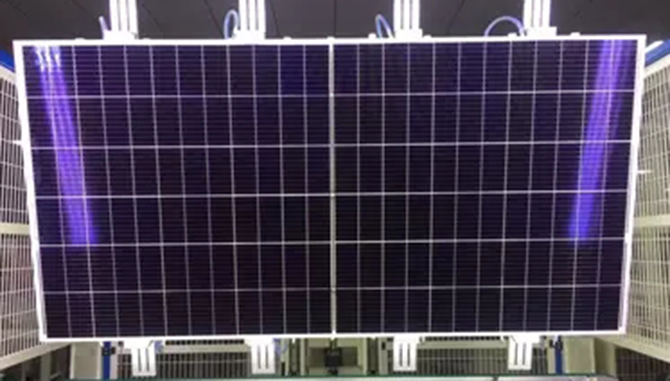

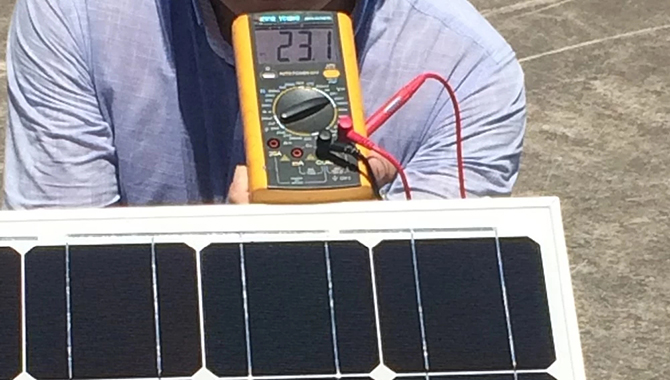

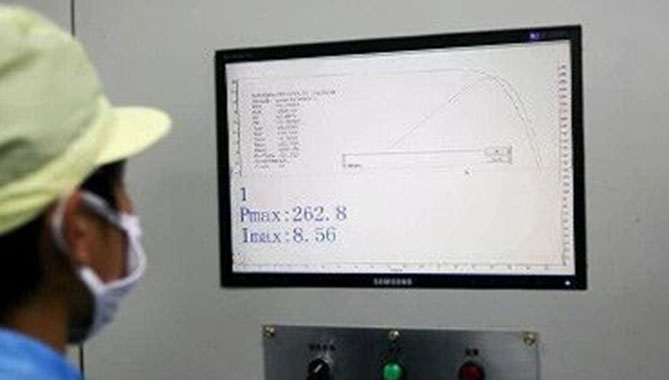

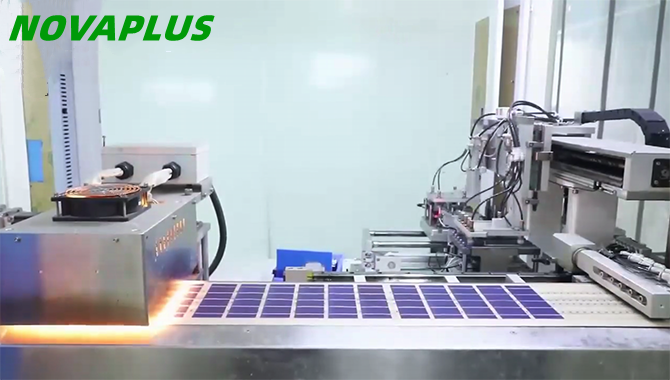

Process inspection includes the first item, Patrol ring inspection, the full inspection of the appearance, and the electrical characteristics are all energized to test. The inspection content is based on the sales order, customer’s requirements, comprehensive check of BOM materials, drawings, inspection regulations, operation documents, equipment operation etc. In order to ensure product quality, the operator must obey "three press", "three automatics", "one control" requirements, prevent defective products in three steps. The aging of products during all production processes must be carried out under controlled conditions and the quality requirements are strictly adhere to not “clearing afterwards”, but “pre-prevention”.

The warehouse-receiving Inspection includes product package, label, barcode and others according to sales order, BOM, drawing, packaging method, weight and other comprehensive inspection check. Making sampling inspection according to MIL-STD-105E II AQL , prevent defective products from flowing into the next process.

Shipment inspection adopts visual inspection, mainly checking if product information and sales order requirements, identification, label, barcode, packaging requirements are consistent, randomly checking the appearance, electrical performance, disassemble inspection, etc to ensure that product shipments 100% fit quality requests and meet customers’ needs.

Nova has obtained ISO9001:2015 and ISO14001:2015 international standard system certificates, and its products have passed IEC62133. CB, KC, BIS, CE, MSDS, UN38.3 and other certificates. We have a complete quality control system process, guided by quality objectives, from new product development introduction, verification and evaluation, trial production, mass production, raw material feeding to process, shipment, after-sales service and continuous improvement and management, making us easily find weak points or abnormal problems in our manufacturing process and quality control inspection process. Then we on site use seven methods of quality control, 5W2H, TQM total quality management tools for analysis or special improvement, the implementation of verification correction and preventive measures effectiveness, to enter a new round of quality PDCA cycle, and continuously obtain quality results and effective quality assurance, to meet customers’ requirements and satisfaction in product quality, service and cost.